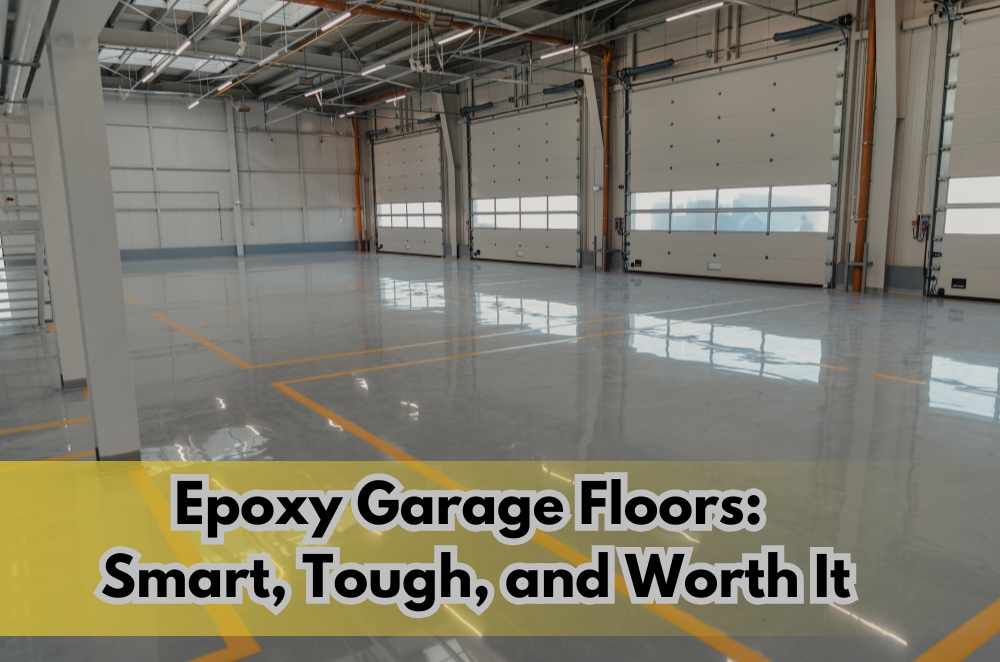

Garages cop a hiding. Hot tyres, muddy boots, and the odd oil spill can make a concrete slab look tired in a hurry. We’ve seen quick fixes fail because they only mask the problem. A proper epoxy system bonds, seals, and protects the entire surface, turning a shed into a clean, tough work zone. If you’re weighing up options, there’s a reason locals lean this way: Builders recommend garage epoxy Sydney for long-term value. It’s not just about gloss; it’s about a surface that shrugs off stains, resists abrasion, and stays easy to clean. Done well, it saves you maintenance, keeps dust down, and makes the whole place safer, year after year.

What makes garage epoxy worth it?

Epoxy delivers durability and hygiene in one hit. It resists hot-tyre pickup, chemicals, and grime, while giving concrete a sealed, easy-to-mop finish.

Under real use, a correctly prepped and coated garage feels different. The slab stops chalking; dust doesn’t settle in pores; spills wipe up instead of soaking in. Slip-resistant additives help under wet wheels. And because the surface is continuous, there are no grout lines or flaky paint edges to trap dirt. Fewer repairs and a longer refresh cycle offset upfront costs. If you’re planning a weekend conversion or a tidy-up before selling, don’t skip surface prep—moisture testing, crack repairs, and profile grinding matter and prep steps are taken before coating floors.

• Choose full-flake for grip and depth

• Add UV-stable topcoats for colour hold

• Include coving to protect skirtings

• Specify non-yellowing finishes outdoors

How does epoxy stand up to Aussie conditions?

Thermal swings, road salt, and beach sand test coatings. Quality epoxy systems handle expansion and abrasion when the slab is prepared and appropriately primed.

Summer heat can telegraph through tyres, softening inferior coatings; a high-solids epoxy with the right topcoat resists that hot-tyre lift. Sand and red dust act like sandpaper, so flake systems or polyurethane topcoats add abrasion resistance. In coastal spots, regular rinsing keeps salts from nibbling at edges. The beauty here is that maintenance stays simple—soft broom, neutral cleaner, a quick mop. If you do mechanical work, drop mats under jacks and stands; epoxy is tough, but point loads can bite. Treat it like a workshop floor, not a chopping board, and it’ll repay you with years of clean, bright service.

• Sweep grit weekly to cut wear

• Neutral cleaner, never harsh solvents

• Use felt pads under storage racks

What’s the bottom line on epoxy?

Most homeowners want value, not vanity. A well-specified epoxy system does both—lifting the look while protecting the concrete and reducing upkeep.

If you’re weighing resin types, look at the whole build: prep, moisture management, primer, body coat, broadcast, and topcoat. That sequence is where durability lives. Skipping steps shortens lifespan; investing in them stretches it. Long term, the numbers lean sensible—fewer patch jobs, less dust, a safer, brighter garage that can swing from parking to projects without fuss. For ballpark ranges and add-on costs that influence budgeting—from flake density to topcoat choice—late in the decision-making process, long-lasting solutions for home and business.

Write a comment ...